Since the introduction of the company's fiber optic cutting machine to the market, it has been widely used by domestic and foreign customers. Whether in the Chinese market, European market, or Southeast Asian market, the mechanical performance, cutting effect, cutting efficiency, and energy conservation of fiber laser cutting machines have been widely praised.

The previous generation of fiber laser cutting machines used a seated operation by the operator. With the improvement of laser efficiency, the efficiency of a worker has also been greatly improved. A worker can operate multiple devices at the same time, and the labor operation cost of the factory has been greatly reduced. Vertical operation is more convenient for employees to switch between different machines compared to seated operation. In this context, the company's R&D center has redesigned the mechanical structure of the laser cutting machine and further optimized the core components, launching a new generation of fiber laser cutting machines.

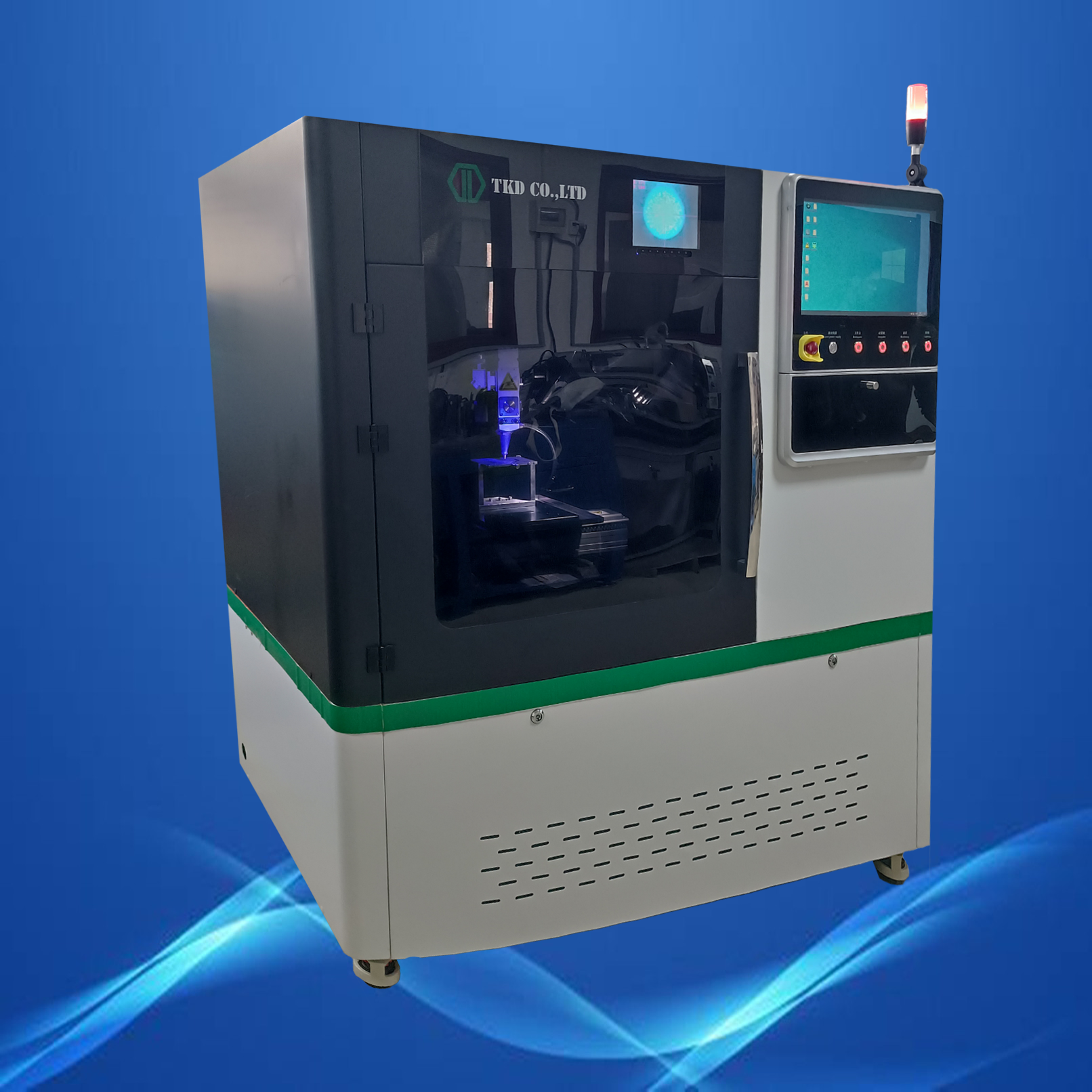

The new generation fiber optic cutting machine adopts a standing operation. According to market feedback, the optimized core components have better cutting efficiency and better cutting effect.

Continuously improving laser cutting machines, continuously enhancing equipment performance, and better meeting customer needs.

If you have a need to cut PCD, PDC, CBN, Ceramic, Tungsten Carbide, please contact us and we can provide you with the best cutting solution.

We look forward to your inquiry.

Email:sale@tkd-hn.com

Whatsapp:+86 13073704020

Whatsapp/wechat

Whatsapp/wechat