As a superhard tool material, diamond has been used in machining for hundreds of years.

In the course of tool development, from the end of the 19th century to the middle of the 20th century, the tool material was mainly represented by high-speed steel; in 1927, Germany first developed carbide tool material and was widely used; in the 1950s, Sweden and The United States has synthesized synthetic diamonds, and cutting tools have since entered a period represented by superhard materials.

In the 1970s, polycrystalline diamond (PCD) was synthesized by high-pressure synthesis technology, which solved the problem of scarcity and high price of natural diamonds, and extended the application scope of diamond tools to aviation, aerospace, automobiles, electronics, and stone materials. and many other fields.

Application of diamond tools

Developed countries have carried out research on diamond tools earlier, and their applications have been relatively mature. Since synthetic diamond was first synthesized in Sweden in 1953, a lot of achievements have been made in the research on the cutting performance of diamond tools, and the application range and usage of diamond tools have expanded rapidly.

The development history of PCD tools

Diamond tools are widely used in difficult-to-machine non-ferrous metals and non-ferrous materials, especially aluminum and copper and their alloys, with a proportion of more than 80%. The affinity between diamond and iron is very strong, and chemical reaction is easy to occur at high temperature. At the same time, carbon atoms in diamond will diffuse into iron, which affects its cutting performance. Therefore, diamond tools are not suitable for processing ferrous metals and other iron-based materials.

Diamond tools are used in various industries

The application of diamond tools in the field of metal cutting is mainly in automobiles (including key parts of engines) and aerospace, in addition to high-precision medical equipment, precision electronic components, etc.; non-metal processing, engineering ceramics, stone, wood, carbon fiber plastic, Synthetic wire, etc.

Various types of diamond tools

According to the processing object, diamond tools are divided into diamond metal cutting tools and diamond woodworking tools, which are mainly indexable and welded in structure. At present, the application range of diamond tools has expanded from traditional turning to drilling, milling, and high-speed cutting, and has been widely used at home and abroad. The rapid development of electric vehicles has not only impacted the traditional automobile industry, but also brought unprecedented challenges to the tool industry.

The development trend of diamond tools

In recent years, the application trend of diamond tools has continued to show an upward trend, and has occupied a dominant position in the CNC machine tool industry. The processing skills of the manufacturing industry are greatly influenced by the diamond tool industry, and the development of the manufacturing industry will also promote the development of the diamond tool industry.

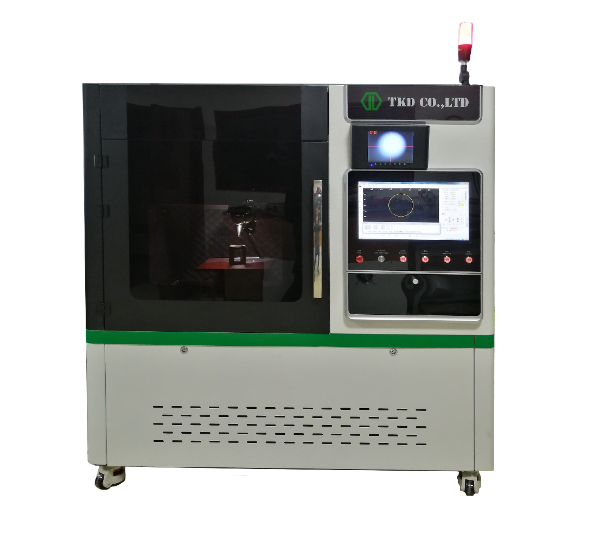

(TKD Fiber Laser Cutting Machine for PCD PDC CVD PCBN etc Cutting)

Diamond tools are becoming the leading tools in the development of aerospace, automobile, electronics and other materials processing, and the application range is more and more extensive.

The development trend of diamond tools is as follows:

1. The use of new diamond tool materials has increased. The toughness of tool materials such as PCBN and PCD is further enhanced, and the fields of application are increasing.

2. The research and development of diamond tools is more targeted. The focus of diamond tool manufacturers' R&D is no longer on generic brands and generic structures. In the face of complex and changeable use occasions and processing conditions, more targeted insert geometry structures, grades and corresponding supporting tools have been developed to replace the general-purpose inserts and tools with grooves and grades.

3. The role of diamond tool manufacturers has changed. From the preparation and supply of pure diamond tools, to the development of new cutting processes and the development of corresponding complete sets of skills and solutions, we provide users with comprehensive technical support.

4. The degree of informatization has been improved, the cooperation of diamond tool manufacturing enterprises has been strengthened, and the market competition has been reduced.

In order to accelerate the optimization and innovation of the tool industry, move towards a positive and healthy development trend, and improve the visibility of tool companies, Diamond Tool Network integrates the advantageous resources of the entire network, and cooperates with industry experts and scholars to provide timely and accurate market for diamond and cubic boron nitride tool manufacturers. Information, high-quality raw and auxiliary materials, help enterprises to grasp the broad development space and many potential business partners. Diamond Tool Network also supports a variety of ways to display tool products and features, reach transactions in the most convenient and fast way, expand corporate business, reduce offline business costs, and solve the problems encountered by tool companies in research and development, production, sales and management. The problem.

TKD CO.,LTD specializes in the research and development of laser cutting technology for superhard materials and the production of related equipment and products, and is committed to providing the best solutions for superhard material cutting

Whatsapp/wechat

Whatsapp/wechat