Fiber laser cutting machine has become an indispensable tool in modern manufacturing due to its high efficiency, precision and flexibility. Especially in the cutting application of metal whisker ceramics, fiber laser cutting machine shows unique advantages. Metal whisker ceramic materials combine the toughness of metal and the hardness of whisker ceramics, and are widely used in aerospace, automobile, electronics and other fields. The following is a detailed solution description for fiber laser cutting machine cutting metal whisker ceramics.

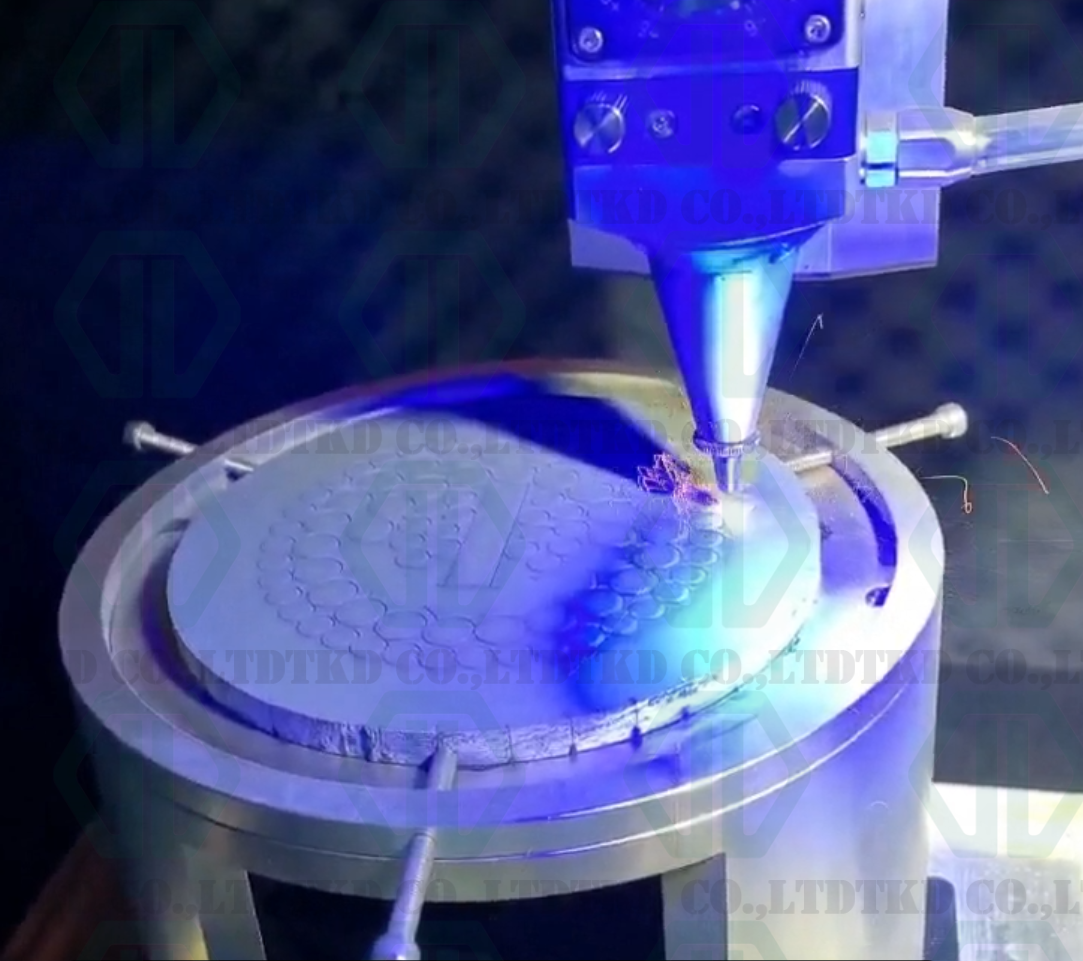

1. Basic principle of fiber laser cutting machine

Fiber laser cutting machine generates a high energy density laser beam through a fiber laser, and the laser beam is focused on the surface of the material through a focusing mirror to form a high temperature area. The laser energy causes the material to heat up rapidly and melt or vaporize. The cutting process is usually accompanied by the injection of auxiliary gas (such as oxygen, nitrogen or air) to help remove molten metal and whisker ceramics to ensure smooth and neat cutting edges.

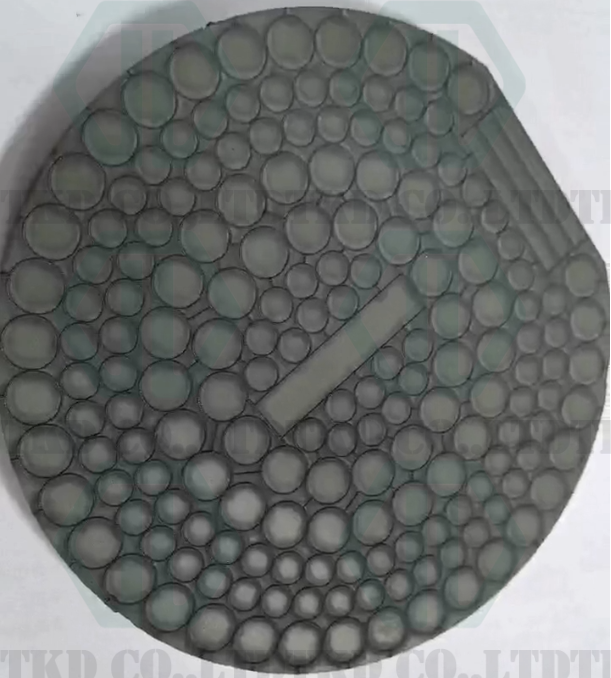

2. Characteristics of metal whisker ceramics

Metal whisker ceramics are a composite material with high hardness, high wear resistance and good thermal stability. Common metal whisker ceramic materials include silicon carbide, silicon nitride, etc. These materials have a low absorption rate for lasers when cutting, making them difficult to cut, so targeted solutions are needed.

3. Challenges in Cutting Metal Whisker Ceramics

①. Low absorption rate: Metal whisker ceramic materials have a relatively low absorption rate for lasers with a wavelength of 1064nm, resulting in reduced cutting efficiency.

②. Large heat-affected zone: During laser cutting, the heat-affected zone of the material may be large, resulting in a decrease in the quality of the cutting edge.

③. Brittleness problem: The brittleness of metal whisker ceramic materials makes it easy to crack during the cutting process, affecting the cutting effect.

4. Solutions

①. Choose the right laser wavelength

Fiber lasers usually operate at a wavelength of 1064nm, which has a relatively high absorption rate for metal whisker ceramics. By choosing the right laser wavelength, cutting efficiency can be improved and energy loss can be reduced.

②. Optimize laser cutting parameters

o Power setting: Adjust the laser power according to the thickness and type of the metal whisker ceramic.

o Cutting speed: The cutting speed should be adjusted according to the characteristics of the material. Too fast may lead to incomplete cutting, while too slow may lead to the expansion of the heat-affected zone and affect the cutting quality.

o Focal length adjustment: By adjusting the laser focal length, the heat-affected zone of cutting can be changed and the cutting effect can be optimized.

③. Selection of auxiliary gas

Choosing the right auxiliary gas is crucial to the cutting quality. Oxygen can increase the cutting speed, but may cause oxidation; nitrogen can reduce oxidation and is suitable for applications with high cutting quality requirements. Select the right gas according to specific needs.

④. Application of cooling system

During the cutting process, the metal whisker ceramic material may produce thermal deformation due to high temperature, so an effective cooling system is required to reduce the temperature of the cutting area and maintain the stability of the material. A water cooling or air cooling system can be used to ensure temperature control during the cutting process.

⑤. Design of cutting head

The use of high-precision laser cutting head can better focus the laser and improve cutting accuracy. At the same time, the design of the cutting head should take into account the characteristics of the whisker ceramic material to avoid damage to the cutting head due to the heat generated during the cutting process.

⑥. Post-processing process

The surface of the metal whisker ceramic after cutting may have burrs or unevenness, which requires post-processing. Grinding, polishing and other processes can be used to ensure that the surface quality of the cut parts meets the requirements. Post-processing can not only improve the aesthetics of the cut parts, but also improve their performance.

5. Application Cases

In the fields of aerospace, automobile manufacturing and electronic components, fiber laser cutting machines have been widely used in the cutting of metal whisker ceramics. For example, in the manufacture of turbine blades for aircraft engines, metal whisker ceramic materials are widely used due to their excellent high temperature resistance. Laser cutting technology can achieve high-precision cutting of complex shapes and meet stringent performance requirements.

6. Summary

The application of fiber laser cutting machines in the cutting of metal whisker ceramics, with its high efficiency and precision, can meet the high requirements of modern manufacturing for material processing. By optimizing laser cutting parameters, selecting appropriate auxiliary gas and cooling systems, and performing effective post-processing, the cutting quality and efficiency can be significantly improved. With the continuous advancement of technology, fiber laser cutting machines will show their unique advantages in more fields and promote the widespread application of metal whisker ceramic materials.

Whatsapp/wechat

Whatsapp/wechat