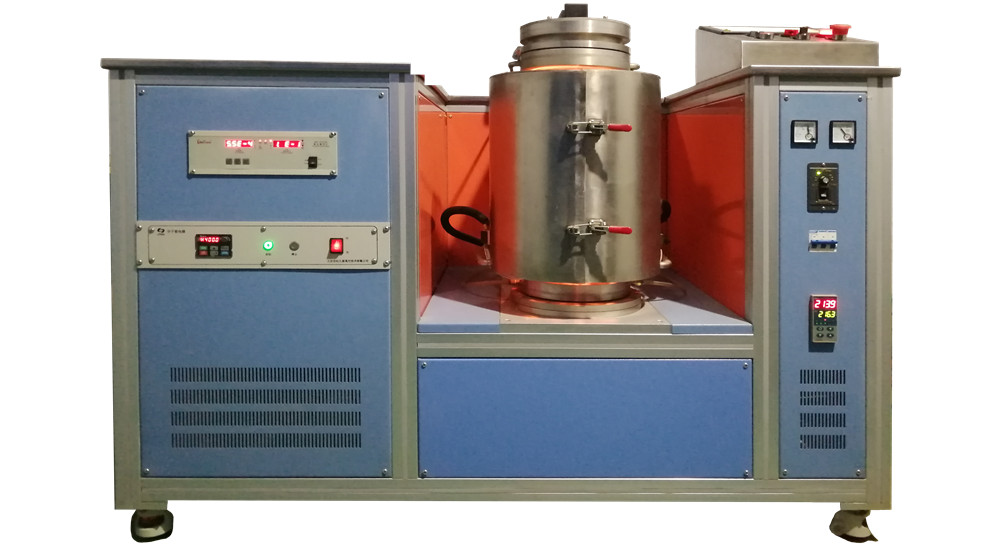

PCD/PCBN Automatic vacuum brazing oven

The Automatic vacuum oven suitable for brazing natural diamond tools, HSS tools, tungsten carbide milling cutters, monocrystal diamond tools, CVD diamond tools, PCD tools, PCBN tools, ceramic materials tools。

It adopts advanced heating methods to greatly improve the heating Efficiency。

The equipment is small, convenient, intuitive and easy to operate, especially suitable for the industry characteristics of super hard tools. Using a small vacuum sealing method for heating and cooling in a vacuum state, personnel without operating experience can easily perform welding operations, which greatly improves the welding quality, welding strength and stability.

Features:

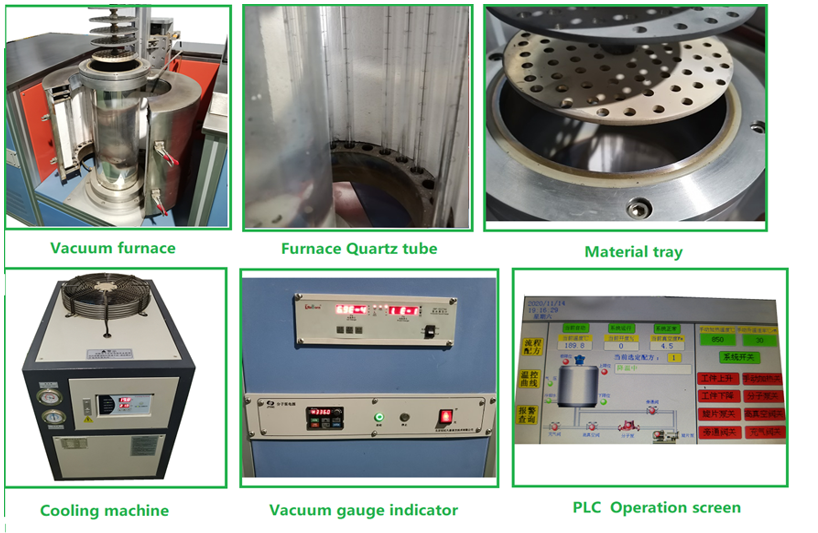

1. Pump system: two stages of pumps to guarantee the precise high and stable brazing vacuum degree at 2E-3Pa. With rotary vane pump (low vibration and noise) and molecular pump (fast response and no pre-heating period)

2. Furnace system: Excellent sealing condition in furnace, infrared quartz tube heating method.

3. PLC and cabinet: Design simply, flexible and friendly to user. PLC program is intelligent to operate.

4. Automatically detect and alarm, intelligent action reacts. when the power is suddenly cut off, the valve will automatically be shut to protect the item in furnace;

5. Multiple interlock protection functions to prevent mis-operation;

6. Water-cooling system protect furnace with safety temperature.

Advantage:

1. High and stable brazing vacuum degree at 2E-3Pa.

2. Running time per cycle is around 70-90 mins for vertical type oven.

3. Running cost per cycle is below 5 Kw.h, saving much for labor cost.

4. Brazing kerf and strength are excellent, stability and consistency are very nice.

5. High brazing efficiency and high production volume (20-40 pcs of cutter /oven,100-200 pcs of PCD/PCBN insert /oven for vertical type)

The equipment detailed parameters:

Item name | PCD/PCBN automatic vacuum oven |

Mode | TKD-160D, TKD-180D |

Voltage | 380V, 3phase, 4 lines |

Heating power | 12 KW |

Machine power | 13 KW |

Power consumption | < 5 kw/h per circle |

Chamber material | Quartz glass, infrared tube |

Chamber size | 180 x 550 |

Stable temperature area | D180 x 200 |

Brazing capacity | 100-200 pcs inserts / furnace, 30-40 pcs cutters/furnace |

Working temperature | 860 degree C |

Max vacuum degree | 5E-4 Pa |

Working vacuum degree | 2E-3Pa |

Loading capacity | 30-40 pieces for shank cutters /furnace 100-200 pieces for PCD/PCBN inserts |

Heating method | Infrared quartz tube |

Cooling method | Water coolant |

Oven Specification | 1520mm L x 920mm(W) x 1000mm (H) |

Machine Net Weight | 400kg+/-20kg |

Packing | Standard export packing with Non-Fumigation wooden case (1 big case+1 small case) |

Brazing procedure 1, Clean tooling/insert tips. 2, Cover brazing paste. 3, Dry and brazing. | |

The equipment details:

Brazing products samples:

Whatsapp/wechat

Whatsapp/wechat