PCD BLANKS FOR CUTTING TOOLINGS

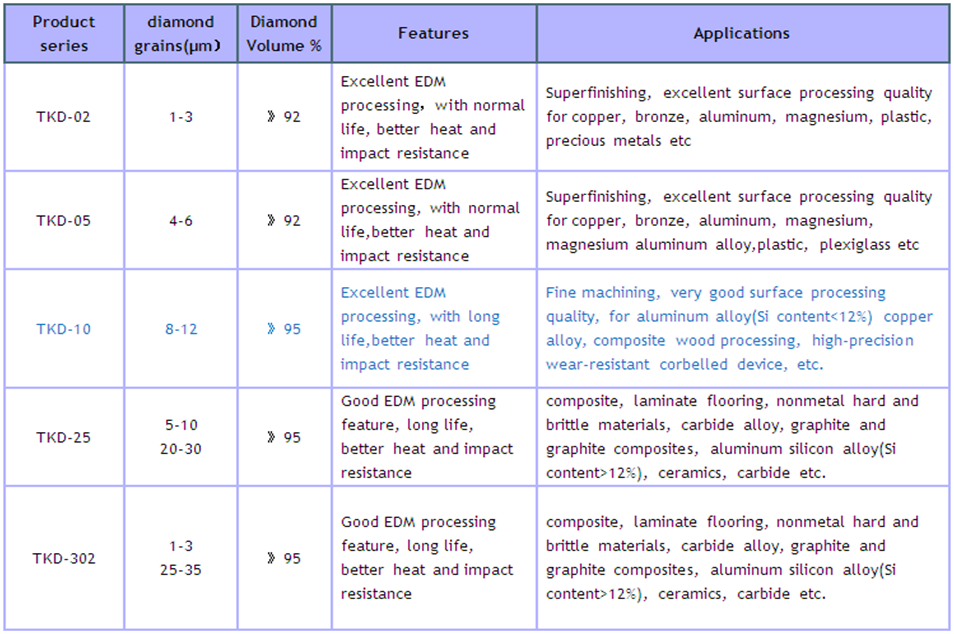

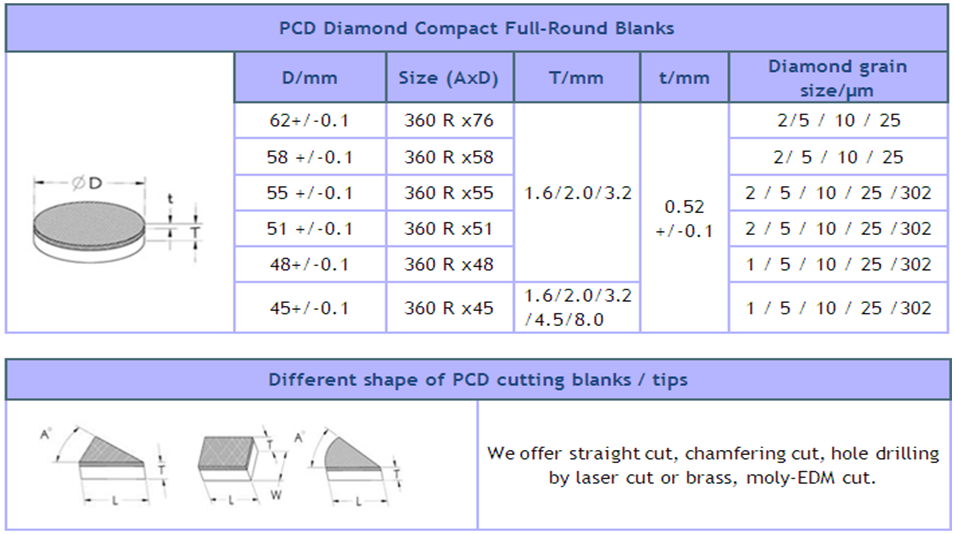

TKD produce the top quality pcd cutting tool blanks with state of art production facilities. We have large diameter of hydraulic press machine for sintering process, pcd laser cutting equipment, EDM cutting machines, C-scan ultra-sonic scanning equipment for cutting and inspection process etc. PCD blanks/ plates/pads are widely used for the machining of non-ferrous metals and alloys, such as aluminum, copper, aluminum / gray iron composites, as well as nonmetallic materials such as wood, chipboard, ceramic,plastic, rubber etc, where high abrasion resistance and good surface finish are required. The products are available in 2µm,5µm, 10 µm, 20µm,25µm,and 2+25µm etc.

Features compared with tungsten carbide tools:

1, The hardness of PCD is 80 to 120 times that of tungsten carbide.

2. The thermal conductivity of PCD is 1.5 to 9 times that of tungsten carbide.Its thermal conductivity is 700W/mk. The PCD blank can conduct heat fast

3, PCD toolings life can exceed carbide cutting tool life 50 to 100 times.

Features compared with natural diamond tools:

1, PCD is more resistant over natural diamond because of its random orientation structure of the diamond particles, and is backed by a carbide substrate.

2, PCD is more constant in wear due to complete production system for quality consistant control, Natural diamond is a single crystal in nature and has soft and hard grains both,when making into toolings, it will not be well using with soft grains.

3, PCD is cheaper and with various shapes and sizes to choose from for toolings, natural diamond is the limit on these point.

Application:

The PCD blank is used in many different fields including aviation, the car industry, electronics,and the wood and stone industry. It applies to varous materials such as nonferrous metal, tungsten carbide, ceramic, nonmetal and composite material.

Materials recommended for cutting with PCD:

Epoxy resins

Gold and silver

Ceramics, unfired

Plastics and rubber

Carbon and graphite

Graphite composites

Fiberglass composites

Chipboard and fibreboard

Zinc and magnesium alloys

Aluminum and aluminum alloys

Copper, brass and bronze alloys

Tungsten carbide, presintered and sintered

Email: sale@tkd-hn.com

Whatsapp/wechat

Whatsapp/wechat