According to the special cutting requirements of ultra-hard materials, our company cooperates with relevant laser scientific research institutes and 2 of largest super hard materials factories to joint together and develop this laser cutting machine; after long-term production Tests and performance improvements, this laser machine performs the best cutting results when cutting various ultra-hard materials with different thickness, such as PCD/PCBN Blanks, PDC Cutters, CBN blanks, CVD Diamonds, ceramics and Alloy. The main performance of this laser cutting machine has reached the highest level of similar products in the world. It is the ideal equipment for cutting super hard materials. The details as follows:

Usage:

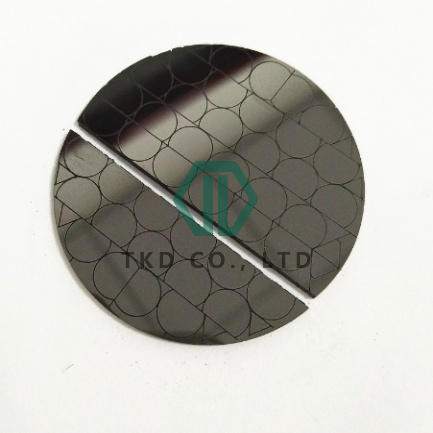

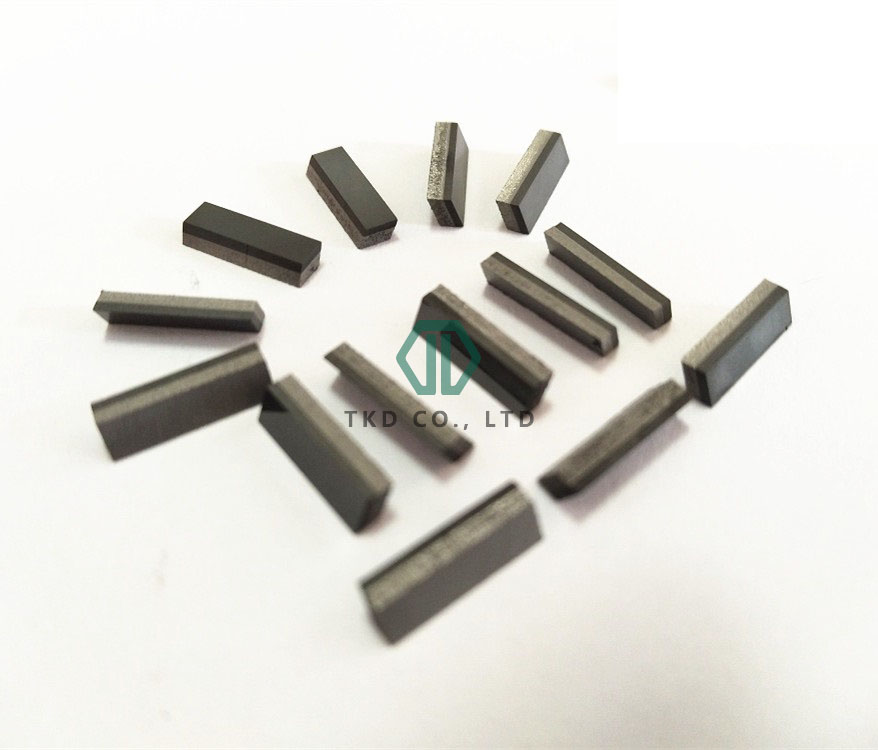

Mainly used for precision cutting ultra-hard materials (PCD, PCBN composite materials and PCD, PCBN polycrystalline materials, CVD single crystal and polycrystalline, and other ultra-hard materials, also ceramic and alloy etc) and other difficult-to-cut materials

See below are cutting elements:

Advantage:

1,High laser technology: Good quality and small divergence Angle, fast cutting speed,

It can be available to cut thicker material with small heat affected zone to save material.

2. High stability of the equipment: the laser power of cutting machine is very stable, and it can work continuously for 24 hours.

No need to debug in daily work with high utilization rate of the equipment.

3. Tailored model of machine can be offered to maximize the potential applications of equipment with economic and practical requirement.

4. User-friendly operation system make the cutting work easy and efficient.

Components:

Laser system (one cavity with two Xeon lamp, two-cavity three-lamps), power system, Laser transmission and focusing system, Control system and worktable, Red laser indicating system and CCD monitoring system, chiller system

Ability to work

①Straight cut

②Chamfering (inclinable within 45 degrees)

③Drilling

④Marking (optional feature)

⑤can work 24 hours, cutting any shape of two-dimensional patterns

| Parameter | Value |

| Max output power | ≥120W |

| Laser Source | YAG |

| Laser generated wave | 1064nm |

| Repeat frequency | 1-300Hz |

| Pulse width | 0.1-0.3ms (adjustable) |

| Repeat positioning accuracy | 1um |

| Max speed | 500mm/min |

| Working platform size | 200mmx200mm;200mmx300mm;300mmx300 mm(choose) |

| Max cut thickness | ≤8mm(single side),≤12mm(double side) |

| Max Load of Working Platform | 15.0kg |

| Power supply | 380V, 3phase-AC, 5wires, 50HZ, |

| Rated power | 12KW |

| External dimension | 1850mm L x 700mm(W) x 1580mm (H) |

| Machine Net Weight | 600kg+/-20kg |

| Maintenance and after sales term | 1-year maintenance of whole set of machine quality, free for change parts except wear parts during maintenance period. |

| Cutting performance | |

| 1.6mm Thick PCD | cutting speed: >120mm/min, Kerf Width: <0.10mm,Heat damage range: <0.05mm |

| 2.0mm Thick PCD | cutting speed: >90mm/min,Kerf Width: <0.12mm,Heat damage range: <0.07mm |

| 3.5mm Thick PCD | cutting speed: >30mm/min,Kerf Width: <0.14mm,Heat damage range: <0.09mm |

Machine size:

Machine details

|  |  |  |

| Blanks straight cutting fixture | Tips straight cutting fixture | Rod/Rotary cutting fixture | Power screen |

|  |  |  |

| Operation display | Laser Cavity | Work table | Xenon lamp &lens protector |

Welcome your inquiry and visit TKD laser cutting machine workshop for checking the machine and discussing for cooperation !

Whatsapp/wechat

Whatsapp/wechat